Factors Affecting Viscosity

As environmental concerns continue to rise, HPMC manufacturers are adopting sustainable practices in their production processes. Many factories are working towards sourcing renewable raw materials and minimizing waste. HPMC is also biodegradable, offering an eco-friendly alternative to synthetic polymers in various applications.

Certain populations, including individuals with allergies, pregnant or breastfeeding women, or those with pre-existing medical conditions, should be particularly cautious with hydroxypropyl methylcellulose. Pregnant women, for example, need to be mindful of all ingested substances, as some additives may have unknown effects on fetal development. Always consulting a healthcare provider before using products containing HPMC is recommended for these individuals.

HPMC plays a crucial role in enhancing the adhesion properties of wall putty. It allows the putty to bond effectively to various substrates, including concrete, plaster, and gypsum. This strong adhesion is vital for preventing peeling or cracking, ensuring a long-lasting finish. HPMC's ability to retain moisture also aids in the curing process, further enhancing the bonding strength.

Understanding Liquid Thickeners

Moreover, HPMC is recognized for its environmentally friendly characteristics. As a plant-derived product, it is biodegradable and non-toxic, making it a sustainable choice for manufacturers aiming to reduce their environmental footprint. This attribute aligns with the growing consumer demand for eco-friendly products and practices, leading many industries to incorporate HPMC into their formulations.

Overall, HPMC is a versatile additive that significantly enhances the properties of mortar used in construction. Its ability to improve workability, water retention, open time, adhesion, and minimize shrinkage makes it an essential component in modern mortar formulations. As the construction industry continues to evolve, the demand for high-performance materials like HPMC will undoubtedly rise, solidifying its role in creating durable and efficient structures.

Properties of HPMC

In the realm of personal care, HPMC is incorporated into cosmetics and skincare products due to its exceptional thickening and film-forming properties. It is commonly found in lotions, creams, and hair care products, where it aids in maintaining stability and enhancing the sensory experience of the formulations. The increasing awareness of personal care and grooming among the Chinese population has led to a growing demand for high-quality cosmetic products, subsequently boosting the use of HPMC in this sector.

Conclusion

Understanding HPMC Viscosity A Key Factor in Formulation

5. Oil and Gas Industry The oil and gas sector has also recognized the benefits of MHEC, particularly in drilling fluids and fracturing fluids. Its ability to increase viscosity and enhance the suspension properties of solids makes it an essential component in these applications, improving overall drilling efficiency.

3. Local Chemical Distributors

In the construction industry, HPMC is employed as an additive in cement-based materials, such as tile adhesives, joint fillers, and plaster. Its water retention properties help improve the workability and durability of these materials. By increasing the open time of the mortars, HPMC allows for more extended working periods, which is particularly beneficial in large construction projects. Additionally, it contributes to the strength and adhesion of the final product, ensuring longevity and performance.

- Regulatory Compliance If you are purchasing HEC for cosmetics or food applications, ensure that the product complies with relevant safety regulations and standards set by organizations such as the FDA or the EU Cosmetic Regulation.

When purchasing hydroxyethyl cellulose, keep in mind any regulatory requirements pertinent to your industry. For example, the food industry has specific safety standards to adhere to, while cosmetics must comply with cosmetic regulations. Always ask suppliers for documentation regarding the product’s safety and compliance with relevant regulations.

In conclusion, Hydroxypropyl Methylcellulose presents a robust safety profile that supports its widespread use across various industries. Its classification as GRAS by regulatory agencies underscores its acceptability in food and pharmaceuticals. Nevertheless, ongoing vigilance regarding manufacturing practices, potential allergic reactions, and quality control remains essential to uphold its safety standards. By prioritizing safety, manufacturers and consumers can confidently leverage the benefits of HPMC, fostering innovation in product development while ensuring public health is safeguarded.

Conclusion

Hydroxypropyl Methylcellulose (HPMC) is a semi-synthetic polymer derived from cellulose, widely recognized for its versatility and effectiveness in various applications. Particularly notable is its use in the production of HPMC sheets, which have garnered significant attention across multiple industries, from pharmaceuticals to construction and food. This article aims to explore the properties, applications, and benefits of HPMC sheets.

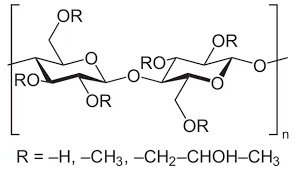

Properties of Hydroxypropyl Methyl Cellulose Ether

Moreover, HPMC is highly soluble in both hot and cold water, allowing for convenient use across different formulations and processes. It provides excellent rheological properties, which means it can create stable emulsions and effective thickeners without imparting unwanted flavors or colors.

The synthesis of HPMC is a critical process that combines chemistry and technology to produce a versatile product with diverse applications. As industries continue to evolve, the demand for high-quality HPMC is expected to grow, driving further innovations in its synthesis methods. Understanding the synthesis process and its parameters is essential for producers aiming to meet the specific needs of various sectors, ultimately enhancing the functionality and applicability of this important cellulose derivative.

The solubility of Hydroxypropyl Methyl Cellulose is a fundamental aspect that dictates its utility across different fields. Understanding the factors influencing solubility, such as molecular weight, substituent groups, temperature, pH levels, and other ingredients, is essential for optimizing its use in various formulations. As industries continue to innovate and develop new products, HPMC will remain a versatile and valuable component in many applications.

HPMC Grades and Their Applications

The construction industry has also recognized the utility of HPMC, particularly in the formulation of adhesives, tile adhesives, and cement-based materials. HPMC enhances workability and adhesion properties, providing a more user-friendly experience when applying various materials. Moreover, it helps regulate the water retention of mixtures, ensuring proper curing and strength of final products.

Applications in Pharmaceuticals

3. Adhesives VAE redispersible powders are commonly used in the formulation of adhesives due to their excellent bonding characteristics. They help in improving the strength and flexibility of the adhesive, making them suitable for flooring applications, woodworking, and other industrial uses.

vae redispersible powder

Another crucial factor affecting HPMC prices is technological advancements in production methods. While innovations can lead to more efficient production processes and reduced costs, they may initially require significant investment. Companies that invest in technology to enhance their manufacturing capabilities can ultimately reduce their operational costs; however, these expenses may initially result in higher prices for consumers until the benefits are realized.

In conclusion, redispersible polymer powders are an essential ingredient in the modern construction industry. Their ability to improve adhesion, flexibility, and water resistance makes them highly valuable for a variety of applications. As the demand for advanced building materials continues to grow, the role of redispersible polymer powders will undoubtedly expand, leading to further innovations and improved construction practices. These powders not only enhance the performance of construction materials but also offer environmental benefits, making them a key component in sustainable building solutions.

What is HPMC?

Hydroxypropyl methylcellulose (HPMC) is a versatile cellulose derivative that has found extensive applications across various industries, including pharmaceuticals, construction, food, and cosmetics. This article delves into the solubility characteristics of HPMC, highlighting its significance in formulation and product performance.

When using redispersible polymer powders, it is essential to consider factors such as the particle size distribution, the formulation pH, and the specific application requirements. Understanding these parameters can help formulators achieve the desired performance characteristics in their end products.

The future of RDP powder pricing is likely to be shaped by several key trends

5. Adhesives and Coatings

In conclusion, HPMC is a valuable and versatile cellulose derivative with a wide range of applications across different industries. Its unique properties, such as solubility, biodegradability, and non-toxicity, make it a preferred choice for formulators. As technology advances and new applications are discovered, the demand for HPMC is expected to continue to grow in the coming years.

5. Experience and Reliability Numerous Chinese suppliers have years of experience in the industry, enabling them to understand customer requirements better and provide reliable products consistently.

Understanding Methyl Hydroxyethyl Cellulose Properties and Applications in China

The Synergy between VAE and RDP